Greater use of all sources of capital – finance, social, environmental – can lead to the creation of more sustainable business models, according to Peter Ball, Professor of Operations Management at the School for Business and Society, University of York.

Talking at a recent Agri-Tech Week event hosted by NIAB, he gave a number of examples of how businesses have leveraged their ecosystems to extract the full value from the value chain.

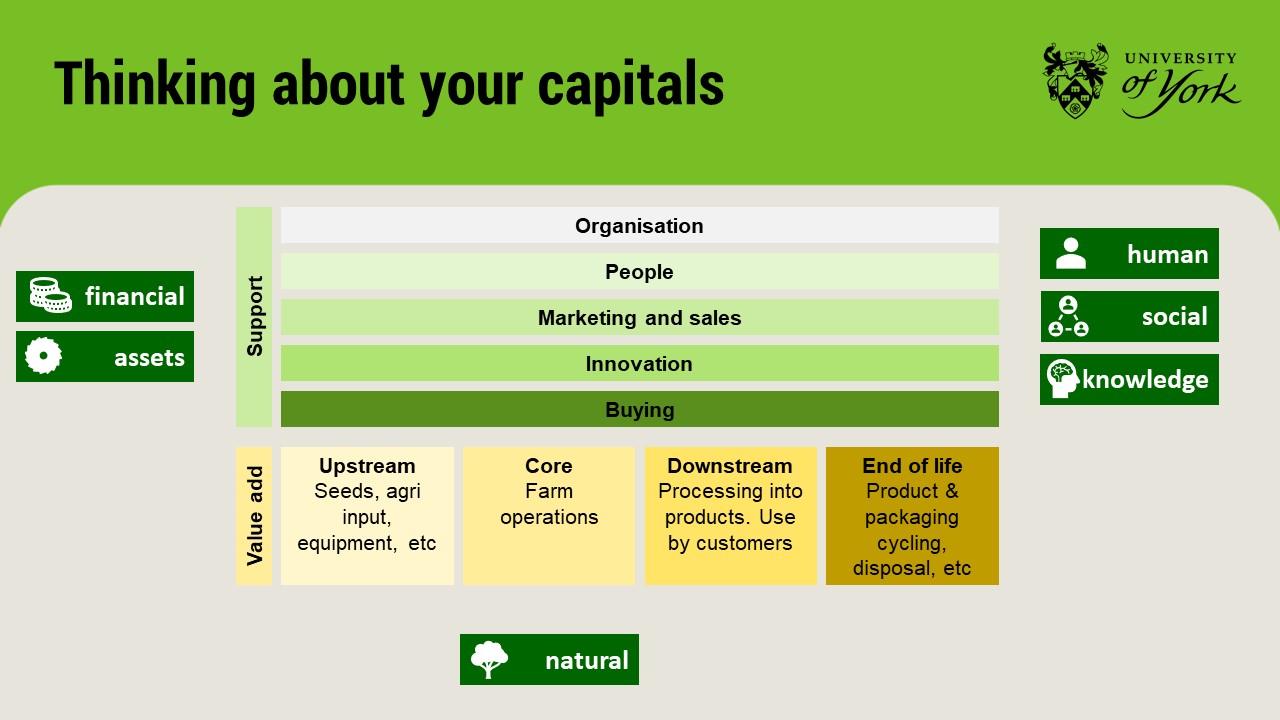

Applying the Porter Model of value chain creation to the agri-food industry, he explained the types of capital involved. In addition to finance there are physical assets (equipment, logistics), human capital (skills, specialist knowledge, networks) and natural capital (land, soil, water).

“While the near market economy benefits from shortage of supply the smaller upstream operations need to be innovative, using human knowledge and social interactions to enable clever things to happen, “ he says.

He gave a number of examples of this.

New services from expert knowledge

The Craft Brewing industry could be perceived as very competitive as it focussed on a niche audience, however the equipment is not utilised all the time, creating opportunities to diversify. Many of the breweries sell beer for the ‘brewery tap’ that is for consumption, but also increasingly are using the by-products for breadmaking and livestock feed for example.

Companies have invested in technology development find they are often asked for advice from other brewers. Rather than consider them competitors, these brewers offer consultancy services and loan equipment when not in use to ‘gypsy breweries’, reducing the cost-base for the industry and working together to grow the market.

Using excess space and specialist skills

Sony manufactures broadcast and professional cameras and camera systems for worldwide markets at its factory in Pencoed, Wales. It found that it did not need all its floor area but had a highly skilled electronics manufacturing team and decided to use this human capital to generate new income streams.

It set up the Sony UK Technology Centre and has developed a highly successful Contract Electronics Manufacturing Service. This provides support to other companies, particularly start-ups that lack the manufacturing skills and may otherwise go overseas. A successful reshoring story includes the production of over 40 million Raspberry Pi computers to date.

The centre includes a class 10,000 clean room facility and bespoke, state-of-the-art manufacturing technology. It was awarded the 2021 National Make UK awards for Innovation and Developing Future Talent.

Collaboration to reduce costs

In UK supermarkets all the wrapped bread made different brands is displayed in bread baskets of uniform size. One company owns all the baskets and is responsible for the logistics, reducing the cost of maintaining and transporting the baskets to the different locations. This company in turn is jointly owned by all the supermarkets so they benefit from these efficiencies.

Using logistics to simplify the supply chain

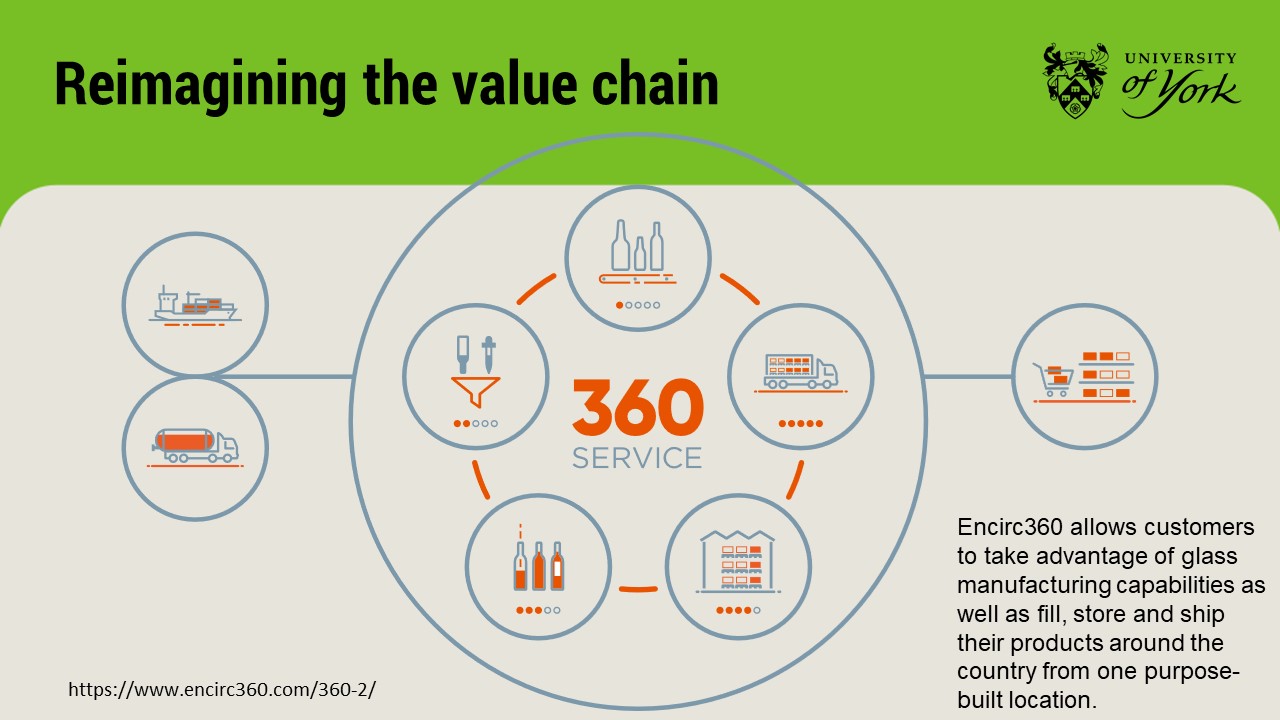

Encirc started business as glassmakers in Derrylin, Northern Ireland. Through acquisition SB Vidros container glass plant in Portugal and a bottling facility near Bristol it has transformed itself into a fulfilment company.

It rebranded as Encirc with a 360 ethos from manufacturing, filling and distributing glass bottles. It creates bespoke pallets of goods for supermarkets and delivers these goods on demand. This reduces the carbon footprint for its customers assisting the industry to reach its Net Zero targets.

The company website claims: “Our unparalleled 360 service allows our customers to not only take advantage of our cutting-edge glass manufacturing capabilities, but also to fill, store and ship their products around the country from one purpose-built location.”

Post written by R&D Today editors from a talk given by Peter Ball at the event ‘Crops to products; building those value-chains’ hosted by NIAB on 10th November 2023.