AI generated digital twins have the potential to transform product innovation and development

Can an AI trained only on theory, not practice, be trusted to adequately and safely control and direct real-world machines? The short answer is no – not without experiencing and learning real-world phenomena. This is why the emergence of ‘Physical AI’ offers a potential step change for new product development, according to Andy Walker, Head of Commercial for Deep Tech at TTP.

Physical AI is the next horizon

Andy explains: “The next horizon is Physical AI, where engineering data such as sensor signals, monitoring inputs and complex camera imagery will provide additional inputs into modern AI models. Previous generations of AI have been successfully used at times in this context, but positive disruption is coming based on modern techniques. This will only accelerate as the models and tools continue to get more capable and industry gains understanding in how best to use them.

“No-one involved in innovation can therefore afford to ignore what’s coming. Anyone who does will lose competitively if they fail to maximise their use of Physical AI. This will have a major impact in both transforming the speed and efficiency of product design and development and in radically improving the performance and the process of controlling products once in operation.”

Digital twins in action

Andy formerly led commercial strategy and execution at McLaren Applied and knows first-hand the benefits of Digital Twins – virtual representations of real-world systems – to mitigate risk and speed up decision-making. He says:

“Formula 1 racing provides a compelling example of digital twins in action. Driver-in-the-loop simulators allow teams to rigorously test new ideas virtually, avoiding wasting time and money in the production and physical testing of parts that don’t end up performing as needed.

“This continues once the car reaches the track. Once the real-world performance at a specific track is experienced, the digital twin can be refined with the data gathered and enable the rapid testing of a variety of settings (such as suspension stiffness, ride height and wheel camber) and recommend changes in the set-up as a result. Ultimately, this can make the difference between winning and losing.

Physical AI creating an opportunity

“However, creating a Digital Twin needs a deep knowledge of the underlying system and creating a functional model is a niche skill. This makes them prohibitively expensive for many use-cases. This is where Physical AI is creating an opportunity.

“AI can reduce the expertise and time needed to build engineering models. By accelerating this first step, product developers can improve and refine designs much further in the virtual world before committing to building costly physical prototypes.”

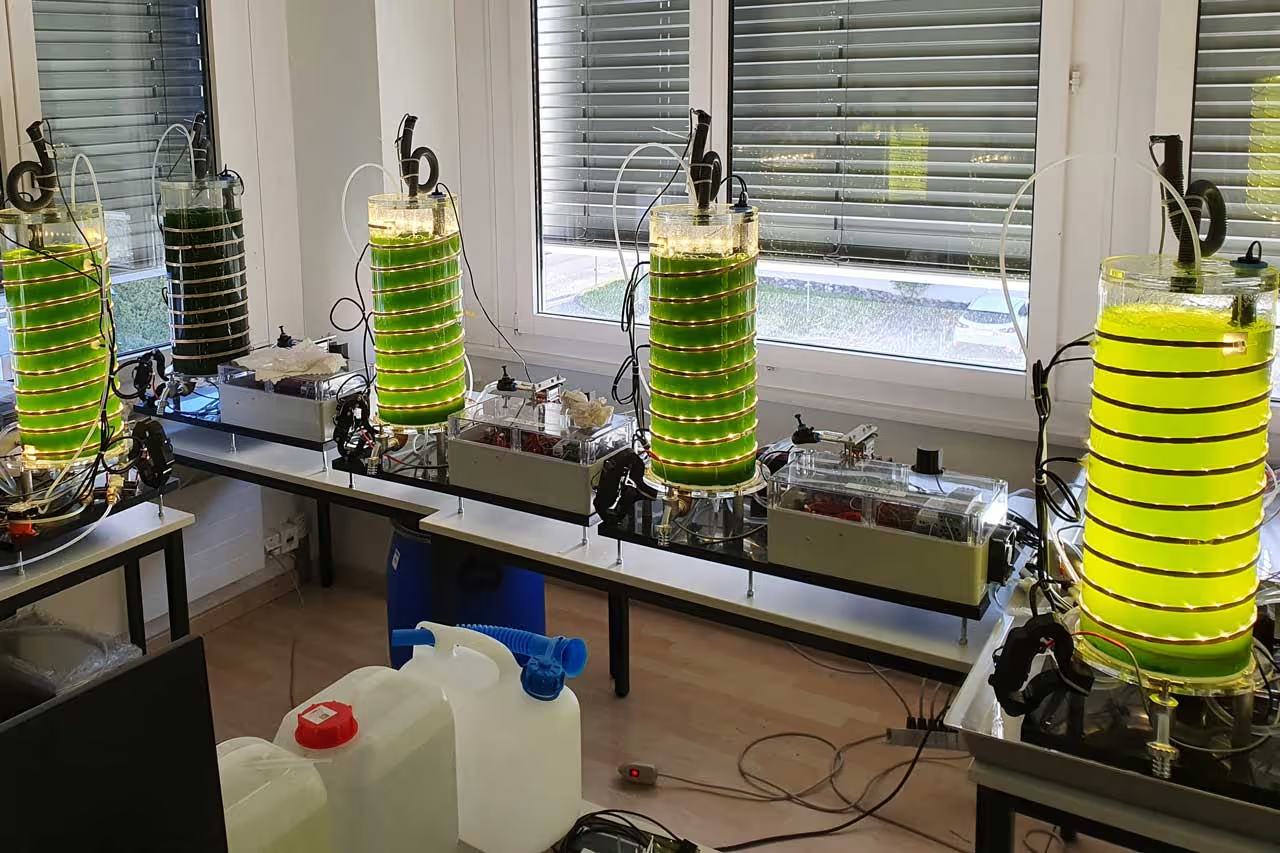

A recent illustration of the value of such a model is a collaborative project between TTP and HSLU, Lucerne University of Applied Sciences and Arts, to develop and scale-up a microalgal bioreactor. Such bioreactors use photosynthesis to sequester carbon dioxide from the atmosphere and make valuable chemicals such as dyes, food additives and pharmaceuticals.

It is a complex challenge to create the optimal bioreactor and costly to build prototypes. TTP modelled the basic parameters – such as cell concentration, algal metabolism, CO2 concentration, nutrient levels, light flux, temperature, pH – that are needed to correctly mirror the function of a photobioreactor.

Also included are equations on mass and heat transfer, and feedback loops such as the effect of algal growth on light penetration.

This ’core module’ was plugged into the equations defining some well-known bioreactor designs, to create a ‘seed’ digital twin. Testing revealed that predictions of cost per unit of biomass and productivity per unit area were in line with expectations, validating the model.

“Through use of the model, the HSLU team are now able to quickly validate new designs without the expense of building prototypes and can therefore reach their goal of high performance and larger scale bioreactors more quickly,” explains Andy.

Will humans or AI ultimately take the wheel?

As Physical AI increasingly drives more rapid innovation and superior product performance, and the line between ‘being trained’ and ‘thinking’ continues to blur, one critical question remains: will humans or AI ultimately take the wheel?

Andy will be covering exactly this question at AI For Innovation, a free virtual conference hosted by LIV.INNO on the 7th May 2025.

Find out more at bit.ly/ai-for-innovation-summit.