“The UK’s net zero economy isn’t just about hitting climate targets – it’s a dynamic and fast-growing sector that’s creating jobs, boosting productivity, and attracting billions in investment. With sustainability at its core, this green revolution is proving that economic success and environmental responsibility go hand in hand.”

CBI report – The Future is Green 2025

“If you’re in R&D management and you’re ignoring sustainability, you are limiting your future job prospects,” says Steve Evans, Director of Research and the Centre for Industrial Sustainability, IfM.

In this interview we ask him about the importance of the energy transition to enabling sustainability and the role of value as tool for determining how to create change for the better.

Toxic side-effects of energy

Since the start of the industrial revolution, we have had abundant energy to do clever things. We use energy to solve problems, but there are consequences of using incredible quantities of energy – it has toxic side effects.

In the beginning, all you did was poison the local river next to the steel mill. But we have scaled manufacturing to the point where it benefits every human on the planet.

Yes, manufacturing is our biggest gift. It has helped drag billions of people out of poverty.

But that same scaling has meant that something that was just a ‘little bit of local pollution’ is now global. That scaling is enormous. We make twice as many clothes in 2025 than we made in 2000, there are twice as many factories, producing twice as much pollution. You can’t keep doing those numbers for the whole planet without creating a massive impact.

The need for change is getting more obvious – we’ve just broken one-and-a-half-degrees centigrade rise over preindustrial norms and are already feeling the impacts.

It is imperative that we find a different approach.

What is the link between innovation and sustainability?

In the world of sustainability, we have this very key phrase called externalities. The pollution that I have been describing is an externality of a production. It is up to somebody else – often the government – not the producer to solve that problem. But we have reached a point where the scale of the externalities isn’t just national, it’s global.

Sustainability is defined by climate scientists, and those that do life-cycle analysis, by emphasising the externalities. Put simply: ‘sustainability is the point where we put zero pollution, such as greenhouse gas emissions, into our various systems’.

They have been really good at explaining the size and shape of the problem by using the urgency and the single dimensionality of climate. And the message is very scary: “If we don’t do something about this, it is threatening our future supply chains.” Even if I’m selfish, as a company I would recognise the challenge.

However, for providing a direction and opportunity for action, one of the best definitions of sustainability is from the Brundtland Report of 1987:

“Sustainability is development that meets the needs of future generations as well as current generations.”

This is the idea that I should be innovating in a way that is not only good for today, but is good for the next N generations, and that is the definition we use as a North star for guiding our work.

Sustainability is a stimulus for innovation

We have in the UK plans to deliver a net zero economy, which includes designing and making things. For progressive companies this presents a strategic opportunity and they respond – ‘we like innovation, and this is a new direction’ – and they see it as a challenge which they’re excited about.

A recent CBI report supports this view.

The net zero economy in the UK has achieved remarkable growth over recent years. Between 2023 and 2024, the sector grew 10.1% and now generates £83.1 billion in Gross Value Added (GVA), with £28.8 billion directly from net zero businesses and £54.3 billion from supply chain activities and broader economic contributions. Every £1 of value generated by the net zero economy creates an additional £1.89 in the wider economy.

We need to change the narrative

For years a powerful narrative has been that decarbonising will be costly. Many firms have bought into this and have come to believe Plan D of the oil and gas industry, which is:

- Plan A: deny that climate change is a thing

- Plan B: deny that it’s got anything to do with people

- Plan C: it’s got nothing to do with oil and gas.

- Plan D: we can’t afford it – it’s a trade-off between the economy or the planet.

There is no evidence for this trade-off, but it has been so well communicated for decades, that it is believed to be true.

It is a given that if you’re comparing a new technology to something that’s had 100 years of scale and learning curve benefits, then the new technology is very likely to lose out.

Wind turbines were more expensive than oil when first introduced, but now they’re cheaper than natural gas. That is why the Chinese are installing solar and wind faster than the rest of the world put together. In fact, China may already have reached its 2035 carbon peak target.

Sustainability as a revolution

Another widely held misbelief is that making a zero-carbon version of the same thing is inevitably going to increase the cost of production. Well, that’s why we’re in the business of innovation – to find a way to do it better.

I think sustainability should be considered a type of revolution, like ‘lean’ and ‘total quality’.

Our research at IfM’s Centre for Industrial Sustainability (CIS) covers the full range of innovation, from what you can do tomorrow morning – simple and direct steps to get you on the journey – through to the impact of transformation and ‘what might the future look like.’

I would consider sustainable innovation falls into four boxes:

- Whole system change – the long-term, big picture view

- Re-purposing and re-combining existing technology – the mid-term view

- Business process change – doing things differently to create a sustainable business

- Technology changes and substitutions – for example new bio-materials to replace carbon intensive manufacture.

We cover the first three boxes at CIS.

1. System change – imaging a future that is biology-based

One prediction is that by 2050, 50% of everything that we produce that’s not food, will be biology-based.

If we look at material science, we’ve been through the age of minerals, metals, and we are now living through the age of plastic. Plastic really didn’t exist as a sector 100 years ago. And yet it’s utterly dominant. Well, in 100 years that will be over.

Hydrocarbon plastics are a by-product of the oil industry, so when we stop digging up oil for petrol, then plastics will get very expensive. Additionally, we’re going to have to pay to capture the carbon that’s gone into making it.

I don’t know which shape will emerge for a sustainable industrial system, but it will be very different. For example, bio-plastics are a viable alternative, still recognisably hydrocarbon chains, but done in a different way.

We do need fossil fuels to create hydrocarbons. You can capture carbon from the air, so we can make plastic by breaking down the waste of the food system to its component parts – hydrogen and carbon – and rebuild it up into plastic. This we can also do in refineries, except they’re bio-refineries.

So, I think there’s a future where there’s still a lot of plastic, but without microplastics and without single use plastic that is lost into the system. If plastic is thicker (3mm), then people won’t throw it away, they will make use of it, it is worth investing in reuse. It is estimated that 50% of plastic packaging could be recycled by improvement of design.

Now there are a lot of people in my world who would argue with this and say they want plastic to disappear. And I’m saying no, there is a possible future where plastic is an important material – and that it is all about creating value so that the life-cycle becomes circular.

This is one example of a really interesting possible future. We can talk about many of those as we do some of that imagining in our research at CIS.

2. Innovating without new technology

Another type of sustainable innovation is where we can combine current known technologies to solve problems in new ways.

One of our PhD students spotted this technology that uses a small wind turbine to capture wind energy, and using the electricity created, we can take hydrogen from a stream, nitrogen from the air and create fertiliser for free.

This creates the opportunity for a farmer can make their own fertiliser by having a wind turbine and a bit of kit. These are all 100-year-old technologies that are now ever more perfected. So why isn’t the world buying this kit in great volumes?

This is the question we have been exploring using multi-level perspectives from socio-technical transitions theory.

This reveals that culture change is vital. Because if energy is expensive, and the oil and gas industry has been giving you these warning signals about sustainability being expensive, of course, you are going to think ‘if I go on that journey, I might ruin my business, it’s too big a risk to change.’

3. Re-thinking the business model

Another thing we can do today, with no new technology, is process innovation (as in management processes, not production processes) to add value.

I once told a whole bunch of cement industry CEOs, ‘ask me to come into your factory and pay me half of what I save you’. So, no win, no fee. Nobody invited me in.

Why wouldn’t they just do an experiment for a few hours and see if it worked out?

I’ve given this example to ministers many times. They say ‘well, that’s a win-win. Why didn’t they take it up?’ And my response is ‘because you’re a minister and you don’t understand the real world –it’s actually a lose-lose.

‘If I go in and don’t save them any money, that’s an enormous waste of time on their part. If I go in and save them money, I’ve made them look bad. So, it’s a lose-lose.’

Since then, I managed to get an invite for a student, Daniel Summerbell, to get into a cement factory. I told him not to collect new data, but instead look at the datasets they had and look for a pattern. He found it and he found a way of saving 20% carbon at zero cost.

This has potential to create a massive impact. Cement is the second most carbon producing industry in the world. We found savings of 20% and didn’t collect any new data.

Another favourite case study is a Toyota factory, which most people would admit is one of the world’s most admired and competent factories.

The Toyota factory at Derby, UK has reduced the energy to make a car by over 80% and the most expensive thing that was purchased was €4,000. It achieved this by turning off all the machines at lunchtime and at weekends.

That’s money spent that was not adding value.

What if the dollar price of energy wasn’t the thing that’s relevant, but the carbon cost?

In a world of cheap energy there needs to a significant driver to give value to a systematic change.

I’m not a big believer in carbon markets until we do it properly.

At $30 a tonne they are going to say ‘How terrible! but I’ll just pass that gas cost on to my customers.’ And because everyone in the industry will do the same there is no competitive advantage to changing the system.

My gut feeling is that charging anything less than $200 a tonne for carbon is not enough to make a difference, and is just a distraction.

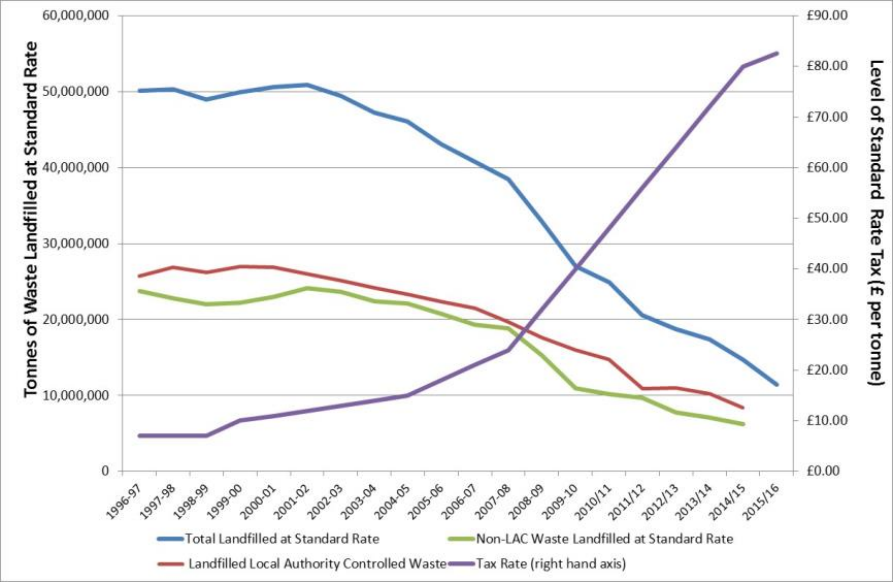

To illustrate this, landfill tax is an interesting example of how to change behaviours.

Changing behaviours with first environmental tax

Britain introduced the landfill tax in 1996 to encourage the diversion of waste away from landfill and to encourage recycling. For the first few years, everybody paid £0 a tonne. But they learned how to fill in the paperwork.

Then in, let’s say year three or year five, it went up to £8 a tonne, and then by the same step every two years. And everybody squealed ‘Oh my gosh, we have to send money to the government, eight pounds a tonne.’

But waste quantities didn’t go down. So, not enough to make you take any action. It went up to £16, to £24, to £32.

The moment when the amount of waste from industry went down dramatically was in the period after it reached £48 a tonne – then Chief Financial Officers started to notice: ‘Have you seen the size of this cheque? Go and do something about it.’ And they all went off and did something about it and waste massively went down.

That’s why I’m taking this lesson into carbon. There’s a number at which the company will take it seriously and act. And the landfill tax escalator has done a really good job; industry has transformed the way it deals with waste. But only after it reached £48 a tonne.

For carbon, I don’t think $25 a tonne is anywhere near that amount. I think it’s $200.

In conclusion – industrial sustainability brings hope

So, we are in a messy place. Some of us working in industrial sustainability have seen this coming for a long time, but now the discussion has become mainstream.

We have learnt that there are four competencies that organisations need to be good at to prepare for a sustainable future:

- Improving efficiency

- Reducing waste by internalising problems and taking control

- Collaboration and coordination within the ecosystem

- Whole system design

But not all is lost. Improvements in eco-efficiency will bring hope in the short-term. In the medium term there are technologies that will find ways to deliver value to all.

But I would say our best hope for the future is system transformation.

Professor Steve Evans

Director of Research in Industrial Sustainability

Steve spent 12 years in industry, finally as Engineering Systems Manager at Martin-Baker Engineering, the world leading manufacturer of ejection seats. He became Professor of Life Cycle Engineering at Cranfield University in 1998 and joined the University of Cambridge Institute for Manufacturing in 2011. He is Director of the Centre for Industrial Sustainability.